Online Partial Discharge Monitoring Distributor

Rapid Partial discharge detection

from a safe distance

Sell-Best offers comprehensive & cost-effective solutions for 24/7 continuous online monitoring of partial discharges in MV/HV/EHV assets such as switchgears, cables, transformers, and motors.

10+ Years of Experience

Since our establishment in 2018, our company has become synonymous with outstanding customer service. Leveraging this commitment, Sell-Best has built strong relationships with numerous clients across a wide and diverse range of industries.

Talk to an Expert

We pride ourselves on delivering rapid, high-quality technical support for your PD monitoring needs. Our team consists of pre-eminent leaders and highly trained experts dedicated to providing excellent service and helping every customer find the precise solution they require.

Best & Low Price Promise

We are serious about offering you the best deal possible! Our focus is on ensuring you receive the lowest competitive price for every identical item we sell. We continuously strive to be your most economical and reliable source.

Types of Partial Discharge Monitoring System

Whether you need just a 1-piece order or a bulk quantity, Sell-Best delivers the best-fit partial discharge monitoring solution to meet your exact specifications. Contact us today to discuss your project and find the perfect solution for your PD monitoring needs.

Blue Jay PD3000 Partial Discharge Monitoring for MV HV Switchgear

- Consists of Display HMI, PD sensor, and wireless receiver

- One device can monitor multiple panels

- Automatic alarm of high PD activity

PowerLogic PD100 Partial Discharge Monitoring for MV Switchgear

- 24/7 monitor partial discharge up to 3 switchgears

- Detects all PD types via capacitive coupler technology

- For MV switchgears

InsulGard Online PD Monitoring for HV and MV equipment

- Works with generators, motors, switchgear, substation dry-type transformers, bus duct, and cable connections.

- Predicts insulation failures before they occur

PDCOM MV Switchgear Partial Discharge Monitoring

- Monitoring the partial discharge trend inside the switchgear

- System based on common capacitive couplers

- One device can monitor up to 10 panels

ASM Permanent Portable On-line Partial Discharge Monitors

- Up to 128/ 32 PD sensors, including HFCT, CC-TEV, Ultrasonic & UHF.

- For cables, switchgear & other HV assets

Astute HV Monitoring® Partial Discharge Monitoring

- For high-voltage switchgear and cables

- Up to 300 sensors measuring critical indicators

- Monitoring up to 180 cables simultaneously

Online PD Monitoring System for Power Cables Rotating Machines MV HV Electrical Assets

- Permanent & temporary PD monitoring

- Automatic notification of PD activity status

DoblePRIME PD-Guard Partial Discharge Monitor

- Monitor up to 12 bushings, either individually or in sets of three

- For transformers, rotating machines, cables, and switchgear.

Rugged Monitoring's Partial Discharge Monitor

- Continuous real-time data acquisition of critical PD activity

- Compatible PD sensors covering various HF to UHF ranges for MV/HV/EHV/UHV electrical assets

Partial Discharge Monitoring System for EHV Cables

- Mobile or online partial discharge monitoring system

- Consists of the detection sensor, signal analyzer, and display

- Automatic alarm for partial discharge

Qualitrol Partial Discharge Monitoring

- Automated PD measurement for MV HV motors, generators, switchgear, and dry-type transformers.

- Real-time detection and analysis of PD activity

- IEC 61850‑certified

Why Choose Sell-Best PD Monitoring

Automated Partial Discharge Detection

Utilizing strategically located sensors on the cable termination or switchgear enclosure, the online PD monitoring system automatically detects various partial discharges, including corona, surface, and void discharges.

Electrical Inspection Safety & Reliability

By continuously, non-contact, and non-intrusively monitoring electrical systems, partial discharge (PD) can be detected at the earliest possible stage. This proactive diagnostic capability is vital, ensuring maximum system reliability and safety without interrupting operations.

Proactive Analysis & Automatic Alarm

Our PD monitoring product delivers proactive analysis and predictive insights, issuing automatic alarms immediately upon critical Partial Discharge activity. This safeguards your equipment by anticipating and preventing irreversible discharge-related damage.

Universal application

We carefully select premium brands that have a proven track record of quality, reliability, and safety. Our products are suitable for a wide range of applications, including switch cabinets, control boxes, cables, transformers, motors, insulators, and more.

PD Monitoring Distributor

Founded in 2018, Sell-Best provides essential Partial Discharge (PD) monitoring systems and sensors designed to detect actual PD activity in generators, motors, transformers, and switchgear. This crucial PD data enables operators to assess risk accurately and proactively plan necessary maintenance.

100% High Quality

We always want you to be able to rely on our PD monitoring solutions. This is why we select products that comply with the highest safety and security international standards, such as ISO 9001.

Low MOQs Support

With our ultra-low MOQs, you can accept smaller projects and pilot new ventures without financial strain. This allows you to rapidly reduce inventory risk and maintain the operational agility needed to thrive in the PD monitoring space.

100% Satisfied with Your Purchase

We guarantee we will supply you with the right product for your application. Our expert team will work closely with you to thoroughly understand your specific needs—from switchgear to cables—ensuring the final Partial Discharge (PD) solution is a perfect match.

Detecting Partial Discharge In Different Applications

Detecting PD in MV Panel Switchgear

Partial discharge monitoring in 1 kV to 35 kV medium-voltage switchgear is mainly used to predict insulation faults in MV equipment. Various partial discharge sensors are typically used in medium-voltage switchgear to monitor partial discharge signals at different locations: busbars and insulators in the busbar compartment, circuit breaker contacts and bushings in the circuit breaker compartment, and joints/terminals in the cable connection compartment, etc.

Detecting PD in MV/HV GIS

Due to the sealed nature of GIS (Gas Insulated Switchgear), Partial Discharge (PD) signals propagate internally with minimal attenuation, often escaping through gaskets or cable entry joints. To sensitively detect these minute internal discharges, specialized sensors—either built-in or external UHF (Ultra-High Frequency) or TEV (Transient Earth Voltage) sensors—are installed directly on the GIS enclosure. Additionally, High-Frequency Current Transformers (HFCTs) are utilized at cable terminations to monitor the resulting pulse current flow through the grounding wire.

Detecting PD in MV/HV AIS

MV/HV AIS (Air Insulated Switchgear) is an open or semi-open structure, allowing internal Partial Discharge (PD) signals (electromagnetic waves, sound, and light) to escape through panels, vents, and openings. This makes non-contact PD monitoring effective: TEV (Transient Earth Voltage) sensors are installed on the inner or outer metal panels to detect the high-frequency voltage transients, while ultrasonic sensors are used to capture the acoustic signals. For comprehensive monitoring, a High-Frequency Current Transformer (HFCT) is also connected to the cable grounding terminal to detect PD activity in the connected cables.

PD monitoring for Dry Type and Cast Resin Transformer

Partial discharges (PD) occurring within dry-type transformers generate high-frequency signals that propagate along the grounding system and metal casing to the equipment’s outer surface. These signals can be effectively detected by installing TEV (Transient Earth Voltage) sensors on the external panels. Furthermore, dry-type transformers also emit ultrasonic PD signals (typically in the 40 kHz range) from wiring sections or connection points. These acoustic signals can be easily captured by externally mounted ultrasonic sensors through ventilation openings and gaps in the casing.

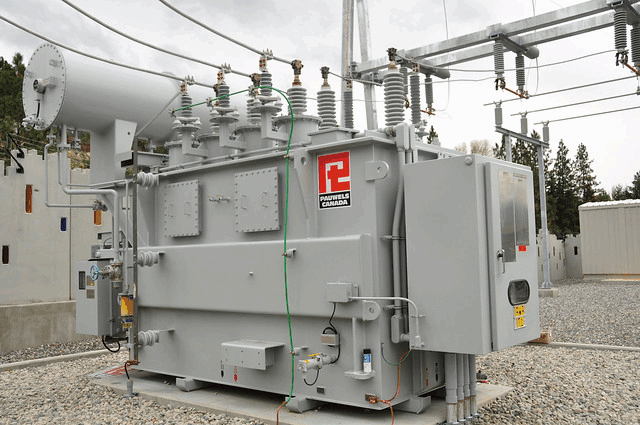

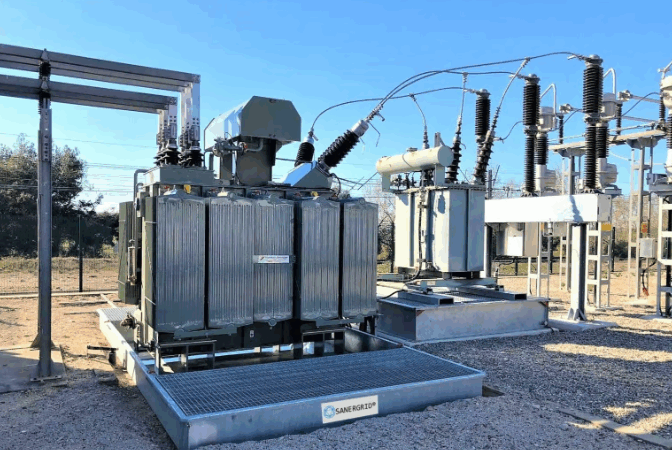

PD monitoring for Oil Filled & Transmission Transformers

Partial discharges (PD) commonly occur within the main oil tank of oil-immersed transformers. Since the PD signal attenuates as it propagates through the oil, a UHF (Ultra-High Frequency) PD sensor is typically mounted inside the transformer tank to sensitively detect the radiated high-frequency energy.

Additionally, PD activity at the transformer’s cable terminations can be detected using both TEV (Transient Earth Voltage) sensors and HFCT (High-Frequency Current Transformer) sensors. The HFCT sensor is effectively used by clipping onto the transformer’s main grounding wire.

Turbo Generators

Partial discharge in the sub-windings of steam turbine generators mainly involves discharge between the winding insulation and the stator core slot walls, surface discharge in the winding end region (exposed to air), and air gap discharge within the insulation. PD monitoring in this context involves permanently installing coupling capacitors on the winding leads or neutral point to acquire and analyze PD pulse signals online.

Hydro Generators

Partial discharge in hydro turbine generators is similar to that in steam turbine generators, primarily relying on permanently installed coupling capacitors to extract high-frequency PD signals to identify insulation aging trends and discharges caused by winding loosening.

Electrical Motors

Partial discharge monitoring in motors is mainly used to identify discharges caused by the stator windings and is commonly used to monitor compressor, pump, and fan drive motors above 3KV. Partial discharge activity is monitored by installing coupling capacitors in the motor junction box or using an HFCT sensor on the grounding wire.

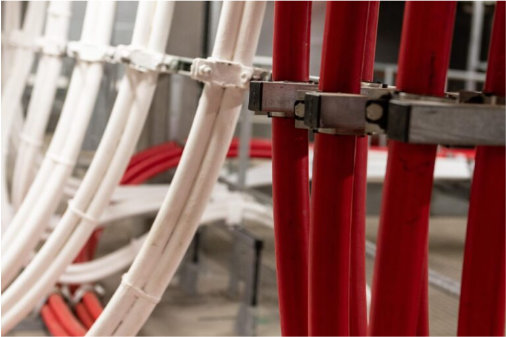

MV HV EHV Cables

In MV to EHV cable systems, Partial Discharge (PD) monitoring is critical as defects in cable accessories (joints and terminations) are the leading cause of insulation failure. This process relies on utilizing a High-Frequency Current Transformer (HFCT) on the cable grounding wire to capture high-frequency PD pulse currents online. By applying Time Domain Reflectometry (TDR) principles, this technology accurately diagnoses and locates PD activity, enabling continuous condition assessment and providing essential early fault warnings for critical cable lines.

Various PD Sensors for Partial Discharge detection

HFTC Sensor: a high-frequency current transformer to be installed on the cable terminals, the clamp version allows installation without out of service.

TEV sensor: a PD sensor with a special design that maximizes the sensitivity and ease of installation directly on the panels of the compartment.

Ultrasonic Sensors: aimed at the detection of partial discharges and arcing at low frequency, for those signals having some kHz content. Ultrasonic sensors are designed to increase the signal-to-noise ratio.

Contact With Us

Contact us to get a free quote and more expertise about our PD monitoring products. Your Project will meet a cost-effective solution with Sell-Best.

Get Quick

Response

- Share your needs with us, We'll contact you in very short time.

- info@Sell-Best.com

- +86 023 6762 8702

- Building 2 No. 88, Jianxin East Road Chongqing China

It is our pleasure to answer your queries related to your business and requirements. Sell-Best will always be behind you and a cost-effective partner for your electrical automation business.